Magnus Flach, maintenance manager, Proplate:

- It took many discussions between me and the designer at Bäckman Blästermaskiner to get the special adaptation that was required.

Magnus Hammargren, responsible designer, Bäckman Blasting machines:

- It was especially difficult to fit the so-called elevator up to the roof between an existing beam system and a traverse that passes over the blasting machine.

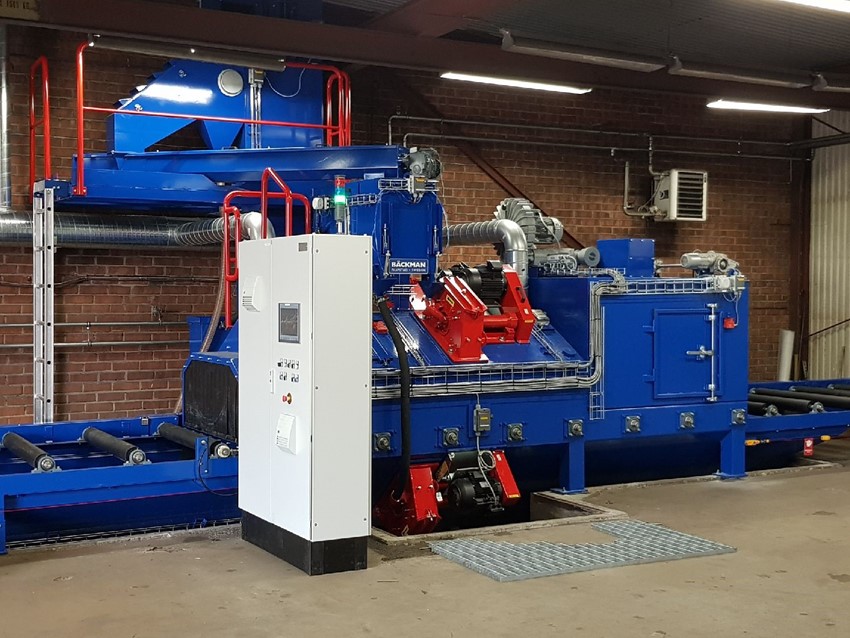

The new machine is built in a harder and more durable material, which means fewer repairs and less service. The system has a modern control equipment with touch panel and will blast details up to 17 meters long.

Magnus Flach: - A big advantage is that we save time in the blasting process. We can now back up and unload the blasted goods much faster than before, which streamlines our production.

Cooperation - a success factor

Both Proplate and Bäckman Blästermaskiner agree that the success factor in the project was the dialogue between them. From Proplate, the initial discussions with the technical salesman, Mika Ström, appreciate the creative issues from construction and from Bäckman, they appreciate the great commitment from Proplate in the project.

Magnus Flach concludes:

- We are very satisfied with the implementation of the project and the facility itself. In addition, we know that if we have problems, Bäckman will show up immediately. They do everything to help us!

Proplate cuts, machines, welds and paints ready-to-assemble components in heavy plate for customers all over the world. The production facility in Oxelösund is one of the world's most modern. Some of the customers are Liebherr, Kobelco, Manitowoc, Nordex Acciona, Toyota Material Handling, Epiroc, Metso and Innovent.

New specially adapted blasting equipment for Proplate

Some time ago, a new feed-through machine was installed at Proplate in Oxelösund, a replacement machine that was to be placed where the previous one had stood, which became a challenge. Above all, it was the low ceiling height that was problematic.